chrisinmtown.github.io

Repairing a Jura Nespresso Machine

Or: The Story of the Oval-Head Screw and Kindness of Strangers

27 June 2010, with many updates

Contents

feedback to christopher döt lott át gmail dðt com

Summary

Machine problems? tl;dr? Here’s the diagnosis quickstart, see details far below.

- What the !@#$%^ are these oval screws? Somebody’s attempt to ensure repair-shop business, you can buy or a build a socket to remove ‘em.

- Push buttons don’t work?

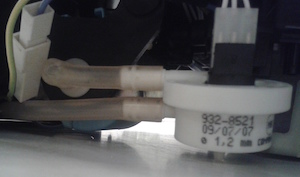

Probably poor electric contact, clean the back of the push buttons and maybe re-apply graphite. - Machine doesn’t draw water?

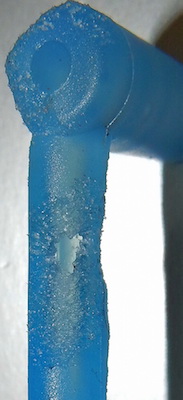

Probably a stuck check valve, free it up with a long thin bamboo stick or by pushing/pulling air via a syringe. - Water leaks out the bottom?

Probably a cracked elbow joint in the high-pressure line from the pump, your only hope is an original part from Europe bcos epoxy will not hold pressure. - Machine won’t turn on?

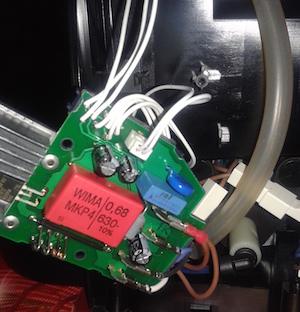

If it’s not bad push buttons, check if the in-line thermal fuses have opened; parts are cheap and are not on the circuit board, so the repair is not too diffcult. - Rapidly blinking lights instead of coffee?

Probably a failed electronic part, here are the usual suspects:- Large rectangular capacitors on the little circuit board have failed for many, replacements are cheap but you have to be handy with a solder iron.

- Temperature sensor in the heater block may have failed. Tiny part so it’s difficult to repair, might need an original part.

My story

A few years ago my family bought me a basic Nespresso espresso machine, which is made by Jura in Switzerland. It uses little sealed coffee capsules like this one:

The upside to the capsules that that they yield a very nice espresso shot, with no skill required and no mess on the counter. The downside is that they are only available from Nespresso and as of 2010 cost US$0.55 each plus shipping. (Update 2021: Nespresso capsules are far more expensive now, but Nestlé lost their monopoly when their patent expired so you can get cheap capsules now, for example at Trader Joe.)

We used the machine for a couple of years, generating a nice recurring revenue stream for Nestlé while making our morning lattes. But over time the power button became recalcitrant. First it required two pushes to go on, then three pushes, then coaxing with a pencil eraser, and this got ever worse until I was standing there for the better part of a minute pushing, pushing, pushing while waiting for the DANGED (ahem) light to start blinking. Naturally it was out of warranty by then, and sending it away for repair was almost as expensive as a new one. I actually eyeballed a new machine in some mall store where I noticed that the latest Nespresso models have a simple toggle on-off switch, so I sorta suspect this power-button trouble happened on a lot of machines.

So off to the workbench, where I found that the machine’s sides are held in place by four screws recessed about 1 inch. And the screws have oval heads. I’d never seen anything like that before, and the security-driver kits at Sears had nothing to offer. The deep recess meant a needle-nose plier would not work. I’ve never seen a consumer appliance protected this carefully.

A quick web search found a special tool on ebay for $40. Ouch! I didn’t know if the machine’s brain was bad or what, and $40 seemed like throwing good money after bad, so I let the machine sit on the bench.

A couple weeks (ok I admit it, it was months) later I found leftover capsules in the kitchen and posted a note to Craigslist for someone to take ‘em for free. I grumbled in my note about the funky oval-head screws and offered to give away the machine along with the capsules.

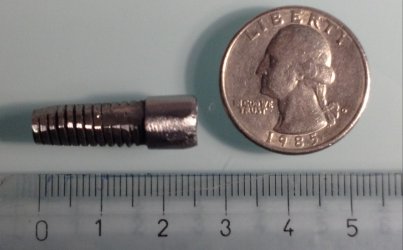

Enter Dave H., a fellow New Jersey resident who responded to my post. His machine had mouse trouble (don’t ask), but he made a socket out of an old bolt! Look at this:

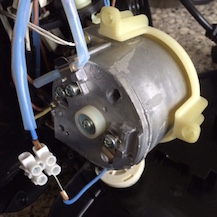

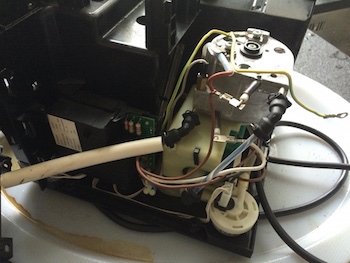

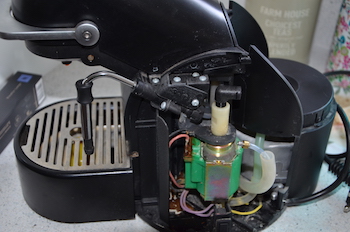

Even better, he sent me the socket!! Complete kindness to total strangers, I love Craigslist. His remanufactured bolt loosened the screws on the very first try. The screws only go into plastic so they require very little force to remove. Here’s the machine with the side panel removed for easy access to the power button. The heater is in front (below the drip tray), and the pump is buried in the middle.

Here’s a close-up of the super secret special swiss oval-head screw (in the middle). I put calipers on it and by comparing it with drill bits estimate that the head is 1/8” at the narrowest and 5/32” at the widest. (Of course it’s probably metric but I don’t own metric drill bits.) Anyhow just 1/32 inch difference is enough. The plain slotted screw I chose as a replacement is on the right.

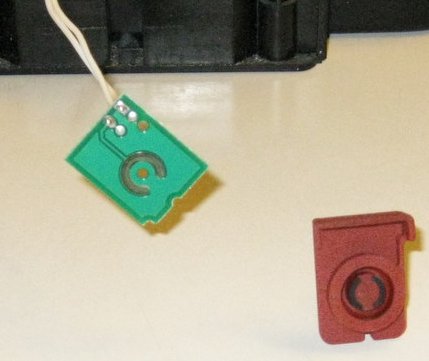

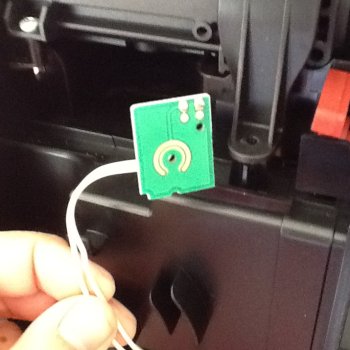

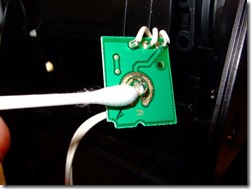

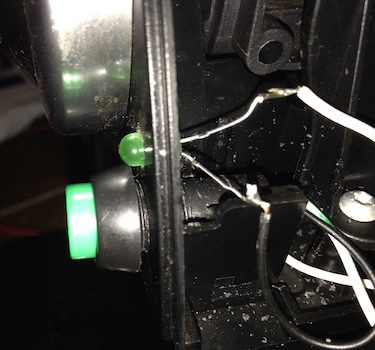

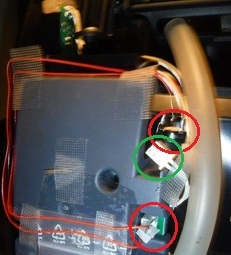

Well, back to the original problem, turning on the machine. The power switch assembly consists of a small circuit board and a molded silicon button. I loosened a bracket behind it (the screw required a Torx driver size T-10) and pulled out the circuit board with the button. Here’s a shot of the board and button:

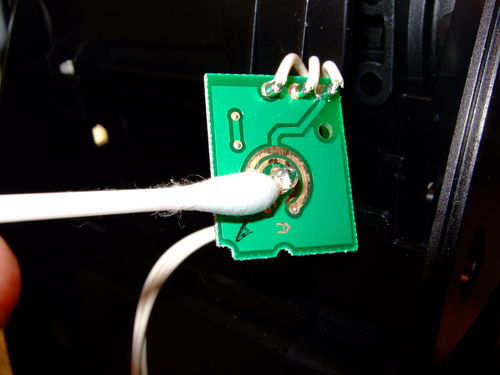

The inside of the button (showing) touches the circuit board when pressed, and springs back a few mm when released. There is no clicky or other moving part on the circuit board, it only has two copper areas exposed, an outer area and a circular inner area (a bit hard to see). Somehow the button completes a circuit when it touches the board. I’m not an EE at all (as has been made very clear to me at work :-) but silicon conducts power?? The end of the button is black as if it were coated in carbon, maybe that’s the secret.

The board didn’t look cracked, so I resorted to the obvious: clean everything. I windexed the board and the end of the rubber button, put them back in place .. and it worked again!! First touch turns on the machine. I was stunned. That’s the happy ending.

If you have one of these machines with power button trouble, the hard part is getting the case open. In my machine the apparent trouble was schmutz blocking a connection. Here’s a side view of the bolt so you can get a better sense for the dimensions, along with the wacky oval-head screw one more time.

Thanks again to Dave H. for making and sharing this little socket. He wouldn’t even accept a pack of capsules for his trouble!

You can borrow a socket if you like. As you’ll see below, various sockets have circled the globe! If you borrow one, you have to send me a picture of your machine’s guts for this page. :) If there’s a queue, you must send it along within a few days. More commonly there is no queue, which means you’ll have to hang on to it for weeks until someone writes me.

You will also need a Torx driver size T-10, it should be easy to buy or borrow locally.

Get a Socket

Buy a socket!

You can buy a tool to extract the oval-head screws on a Jura nespresso machine:

- A 3.5 millimeter, 6 point socket may work. If you don’t have a set

with this size (I don’t either, mine starts at 4mm), try this:

https://www.amazon.com/Wiha-26535-Precision-Driver-Metric/dp/B000O5ILYS/ - A steel oval-head socket is about US$13 shipped, sold by Peter N, the

Jura Capresso Doctor on eBay. This has been used successfully by many people:

https://myworld.ebay.com/juracapressodoctor - Peter N. fabricates his own steel sockets in Greece and sells them for about $10 on eBay:

https://pages.ebay.com/link/?nav/item.view&id=291262252009&globalID=EBAY-US - 1/4 inch bit for oval screw heads from Esprase in The Netherlands,

€6.75 plus shipping:

http://www.esprase.nl/product_info.php?products_id=569” - Oval Pan Head Security Screw Hand Driver, about US$12 plus $8

shipping. I have not seen this tool and cannot promise it’s the

right size. If anyone buys one, please send me a picture.

http://newelectronx.com/proddetail.php?prod=oval-pan-head - Spanner bit (driver) size 10 at Amazon, about US$4 plus shipping, eligible for free shipping. A spanner bit is actually made with two points for driving a security screw that has the matching two little holes on the screw head face. But the tool has a gap between the points that’s just about right for turning the Nespresso oval-head screw! See below for reports and pictures about using a spanner bit to turn the oval-head screws.

http://www.amazon.com/Vermont-American-15442-Spanner-Screwdriver/dp/B000GAQE8Q

Unfortunately the oval pan-head security screw bit is not supplied in any tool sets that I’ve found. For example, these sets from Harbor Freight (links below) look promising, but Gregg L. checked them out in person and reports that the needed bit is not included.

- http://www.harborfreight.com/33-piece-security-bit-set-93388.html

- http://www.harborfreight.com/100-piece-security-bit-set-68457.html

Build a socket!

If you already have your machine on the bench and don’t feel like waiting for a tool to arrive in the mail, look below for some advice on building a tool to turn the oval-head screws. Reusing a part from Ikea seems to be the easiest option.

In April 2009 Jakou posted details on reworking a part from Ikea into a socket to turn these pesky oval-head screws. He reused a fastener that Ikea ships with their furniture (see picture at right). This fastener is about 2.8cm (1 1/8 inches) long and consists of two parts: a hollow sleeve plus a matching M4 (metric 4mm diameter) screw. An Ikea store often will give these out on request but sorry I don’t have a part number. The only required tool is a pair of pliers to squeeze the open end of the sleeve. The picture below is straight from his blog.

Read the whole discussion (en français!) at the link below. If you don’t understand French, a Google translation is pretty good. Many thanks to Elvire Serres for sending me this link:

http://www.tout-electromenager.fr/forum_lecture-4775-4-1.html

Also scroll down to see more details about Ikea bolts from Mr. Arenas of Barcelona.

Mico N. of The Netherlands offers this advice to build a metal socket:

What I did was look around for an aluminium object (which can be drilled easily) and would fit nicely in the recessed holes my machine has to get to the oval head screws. Some were recessed 30 millimetre deep. My eye caught this scalpel-like hobby knife holder and it is a perfect match! You can buy these knives in the hobby shop for a few Euros/Dollars. I measured the thinnest part of the oval head screw with a caliper and this turned out to be exactly 3.2 millimetres. Luckily I still had a 3.2mm metal drill in my toolbox so I placed the hobby knife holder in the vise and tried to drill a hole as much in the middle as I could. As you can see from the photo I need more practice to find the middle :-) After drilling a hole into the knife holder of about 5mm deep I moved the drill from left to right in a straight line to make the hole into an oval shape similar to the screw. After a while it was a perfect fit and I successfully used my “tool” and unscrewed the oval heads from my Nespresso machine.

Jacopo L. of Milano, Italy offers this advice to build a plastic socket:

Just take a pen (a Bic is perfect for this job). Pull out the bottom cap and the ink cartridge. Heat the tip of the casing a bit just to melt the plastic and make it soft. Then press the tip on the oval head and wait 30 seconds to let it cool down. Done. Now you have a perfect tailor made oval screw driver!

However, several people have written me to say that they had poor luck with making a plastic tool. They melted several Bic pens but still were not able to turn the screws. So your mileage may vary here.

In August 2011 Rolfje blogged with advice on opening a Krups XN2001 machine, read it here:

http://rolfje.wordpress.com/2011/08/27/how-to-fix-a-krups-xn2001-nespresso-machine

He glued bits of metal with a slot to the oval screw heads. The picture is straight from his blog:

Need parts?

Here is a resource.

- Peter N, the Jura Capresso Doctor, sells parts for Jura and

Jura-Capresso machines, at present thru eBay. But since the

Nespresso machines are made by the same Swiss manufacturer

(Eugster-Frismag) that makes the Jura, some of the parts like

internal O-rings may work for Nespresso machines too.

http://myworld.ebay.com/juracapressodoctor

Machine Repair Stories

Below I’ve gathered pictures and stories of machine repairs – some successful, some not. Many machines were opened with a socket that I’ve lent out. :)

If you prefer video over text, here’s 15 minutes of explanation on

opening and repairing a machine:

http://www.youtube.com/watch?v=CDdAWKuCvhA

Stories in 2010

30 July 2010

Dave’s socket traveled to San Francisco, CA to help Thayne N. repair his Nespresso D90. Success!

27 August 2010

The socket returned to SF, CA to help Jim C. fix a loose wire in his Jura Ultra. Success number two!

29 September 2010

Third trip to California, this time to Jen L. in Encinitas. She opened her Essenza and convinced both sets of push-button switch contacts to work again! That’s three successes and counting.

11 October 2010

The socket flew over the pond to Bert van E. in Utrecht, The Netherlands. He got his Krupps Cube open just fine, but the problem preventing the machine from turning on was not obvious. Have to count this one as a miss, unfortunately.

22 October 2010

The socket continued its European journey to Geneva, Switzerland. There it helped Tony T. open his machine and clean the contacts, the same repair that I did some months ago. Success number four! He sent me these before and after pictures of the contact circuit board.

9 November 2010

Back to North America, the socket made its first stop in Canada, where Antoine N. in Montreal used it to open his D100 and re-clamp a leaking hose.

19 November 2010

Fourth visit to California! Bill V. of Northridge used the socket to open his C100 and clean the power switch contacts. His machine’s switch has three wires, a small LED in the middle of the board, and a translucent rubber push button. He reports that it works fine again.

10 December 2010

First visit to England. Tom Q. in Basildon, Essex, UK used the socket to open his Siemens machine. Unfortunately the fault was not in any obvious places like the switches and he was not able to repair it.

18 December 2010

Back to the U.S., the socket visited Illinois, the Land of Lincoln, where Ivan B. used the socket to open his Jura F60.

28 December 2010

Akos B. from Hungary wrote me that he found a simple tool to loosen these oval-head screws. It’s called a spanner screw bit and Akos reports that size 10 worked for him. I bought a size 10 from Amazon. It fits but does not grip the head very well.

Stories in 2011

3 January 2011:

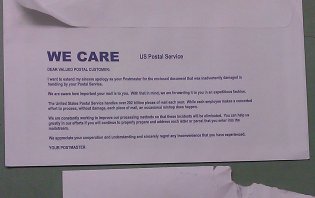

Lost. :-( The USPS ripped the envelope that Ivan used, and the original socket fell out somewhere on the way from Illinois to Philadelphia. Ivan very generously offered to buy one of the Ebay guy’s sockets to keep this little community going.

10 January 2011

Ivan replaced the home-brew socket that our beloved USPS dropped on the floor with this shiny new one and sent it on to Philadelphia.

14 January 2011

Sam G. in Philadelphia opened his C100 and began searching for an elusive leak!

23 January 2011:

Visited Travis E. in Newton, MA. He cleaned his machine’s buttons and they work again!

13 February 2011

First time in Portugal! Paulo P. pried open his machine and polished away the poop that prevented his push buttons from working properly! (Forgive me, Paulo :-)

28 February 2011

Second person in Portugal! Eduardo N. opened his machine and sent me this picture.

7 March 2011

Next stop was Spain, where Manuel L. in Madrid reported finding some metal bits inside the socket that made it difficult to turn the oval-head screws. After some cleanup he was able to open his machine and diagnose a failed pump.

6 April 2011

Third visit to Portugal, where Adão C. confirmed that the socket is a bit damaged but still functional. His machine had the same problem as mine, and after some cleanup it worked again!

1 June 2011

After nearly two months with no requests, David R. of Chicago wrote me to ask for the socket. He sent me this picture and note:

in about 10 minutes the machine was dis-assembled, cleaned, re-assembled!

14 June 2011

Second stop in Chicagoland to help Gabe S. open and repair his D290 with excellent results. Gabe reports that he replaced the original screws with #6 x 1/2 inch stainless-steel sheet metal screws.

11 July 2011:

First visit to Asia! Melvin P. in Singapore finally convinced those pesky oval-head screws to turn with a little help from some aluminum foil stuffed into the socket. And he helped a friend too. He reports:

I also realized (rather belatedly, after earning a bruised thumb) that the tool works much much better when it is detached from the key ring and used with a screwdriver handle attachment (the blue object in the photo). While the key ring can provide the necessary torque leverage, you really need a handle to provide the needed pressure to keep the bit on the screw head.

12 July 2011

The socket is significantly damaged. Melvin P. sent me this close-up picture. To be fair, the ebay guy does say this tool is for light use only. Melvin reports that he reworked it a little and it should still work.

20 July 2011

Ralph ? wrote me from Cyberspace to say he successfully used a #8 spanner bit to remove the screws in his machine. He reports:

the space in between the prongs on the bit make a very tight fit at exactly the most narrow diameter of the oval. it takes several attempts, much slipping off the rounded head, a very good sense of the axial center of the screw, and a steady hand to get the sufficient friction to get the screw started.

21 August 2011

Gregg L. of Hatfield, PA wrote me about his success with fixing his machine:

Appreciated your suggestions and pictures. Used the idea from Mico N. and drilled out an X-acto handle as described using a number 31 drill bit with no vise, since I don’t have one. Worked perfectly. The Harbor-Freight security bit set did not have an oval head driver and the bi-slot bit did not work even with some filing. Did use the small Torx bit from the set however to remove the top shield to make getting to the buttons easier. Had a right hand button that would not activate. Took it apart cleaned everything with rubbing alcohol and cotton swabs. Reassembled it with 4x1/2 zinc pan head screws (they are a better fit than 6x1/2) from Lowes ($1.25), button now works and wife is happy again.

28 August 2011

George X. in Shanghai, China opened his machine with the socket but had some trouble with the internal fasteners.

24 September 2011

Lawrence Sheed of Shanghai sent me a link to detailed instructions on

his blog for opening a Nespresso Cube (Krups XN5005). The oval

security screws on that machine are not set deep, and he was able to

turn them with pliers. Check out his pictures!

http://www.computersolutions.cn/blog/2011/09/repairing-a-nespresso-cube-krups-xn5005

9 October 2011

Giovanni R. in London, England used the socket to open his machine. He kindly repaired the socket before sending it along.

19 October 2011

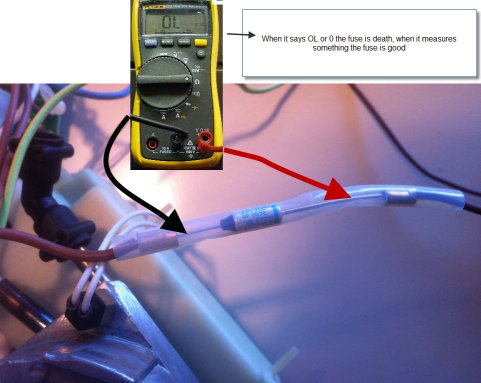

Niek V. of Arnhem, The Netherlands disassembled his Nespresso Cube after making further adjustments to the aluminum socket. He diagnosed two blown thermal fuses and replaced them successfully! He reports:

I fixed the Cube yesterday, it was so easy with the right tool! The 2 thermo fuses screwed to the heating element were defective, so I replaced them for €3,50! At Nespresso they asked €150,- for repairing it! To find the problem I started to measure voltage from the connector (230V 50Hz) to the printed circuit board to see if there is a strange value. From the connector it goes first to the on/off switch and from there to the 2 thermo fuses. The values were right (230V) until I measured after the fuse, there was no voltage, then I measured OVER the fuse with an Ohm meter (resistance). It should give a value greater than 0 but it was 0 or OL (infinite resistance), so then you know the fuse has done its work and is broken. So I took them out and read what was on them. My fuses are: Microtemp, Stabln, E5A00 167 C (degree), so I went to the electronics store and bought 2 thermo fuses http://www.amazon.com/Thermal-fuse-167-degrees-celsius/dp/B000T9VESY (they are also available at Amazon). I replaced them, put it all back together, pushed the on button and it worked. The result was a fine cup of coffee!

2 November 2011

Niek V. wrote me about a new socket!

I already told it, the socket is damaged and you need to fix it after a few screws. So I made a new one today and it just works fine. The next one who’s going to need it gets them both so he can decide which one to use.

4 November 2011

Bruce F. of Long Beach, California wrote me about his regular drip coffee machine:

Thanks to your blog, I’ve just been able to open up my Krups 12 Cup Coffee maker model 134A. The 3-max cups switch was broken. There are two oval head screws about 1 inch deep on the bottom that needed to be taken off. I was able to make a similar tool to those that were described, however the dimensions on the head of these screws were 5mm at the narrow side and 6mm on the wide side. Hope this helps someone else.

21 November 2011

Manny C. in Princeton, TX opened his Capresso to fix a leaky hose.

24 November 2011

Diana T. in Los Angeles writes:

Let the folks know that all the advice was great and it worked perfectly. Machine fixed in exactly 10 minutes. We replaced the funny screws with the ones suggested by the blog and now our cat Frankie can get her morning coffee (without it she’s a MONSTER).

6 December 2011

Julie P. in North Wales wrote that she used the brass tool made by Niek to remove the screws on the bottom of her machine. She cleaned the power switch and is now searching for the source of a leak.

7 December 2011

Noel L. from Puerto Rico reports the following experience:

I also noticed that if you pinch the soft button from the outside, and pull it out at the same time, it starts working again. Somehow, accumulated dirt or sulfate is removed by pinching and pulling the button. This is really convenient especially if you are in a hurry and do not have time to uncover and repair the machine. I hope this helps some Nespresso coffee lovers out there.

Second update 25 June 2014 from Noel:

Today, I would like to update the same problem with another experience that will help many friends fix their clogged buttons without breaking apart the machine:

When pinching the buttons do not do the trick, if you spray a small amount of Silicone Spray on the power on and cup buttons, while having the machine at a horizontal position, this liquid will penetrate and reactivate the electric connection again and the machine will start working properly. Silicone acts like a cleaner and conductor and it dries very quickly. I use it also for my stubborn iphone home button and it works better than alcohol plus lasts longer. Although I don’t think the brand matters, the one I used is Liquid Wrench.

Thanks for maintaining this very useful blog.

10 December 2011

Nick H. in London, England wrote me to say:

Unfortunately the aluminium one is pretty chewed up and won’t work. The brass one will not fit either as there is a ridge around all of the screws on my machine and the brass tool is too wide.

27 December 2011

Ricardo R. in Mafra, Portugal wrote me about trying to open his Nespresso xn2001:

Although i’ve already tried to open the Nespresso, but the alluminium socket is very damaged…and the other doesn’t fit…

I told Ricardo to keep these sockets since they don’t seem to be of any further use to anyone.

Stories in 2012

5 January 2012

Dennis van D. in Utrecht, The Netherlands wrote me to report his success with using a #10 spanner bit:

Thanks to Rolfje and your blog, I managed to open and repair the dirty buttons on my Krupps Nespresso :) Since I’m rather impatient, waiting for an envelope with a tool while the machine’s already on the table is not something I’d like to do. Thankfully I saw a tool come along that I had lying around (#10 spade bit), so I could start dismantlement right away. It was a bit finicky with the first two screws, but the 3rd and 4th came out as if the bit was made for it. Thank you for making my mornings a bit less annoying ;)

16 January 2012

Todd S. from Cyberspace wrote me to report his experience with using a screw extractor on the oval-head screws:

Thanks for your article about the Nespresso machine repairs. I was ready to bust out the soldering wick and get geeky on that thing (it’s the office machine). Alas, the oval screw heads were a surprise. I attempted to make a plastic “tool” using a pen (as someone suggested). Then, it dawned on me that the easiest and cheapest solution was to drill a small hole into the bolt head. Then, I simply used a bolt/screw extractor to remove the factory screws.

While drilling the hole into the top of the slightly-rounded screw-head isn’t too terribly difficult, it does require a bit of patience and concentration. A very simple and durable “helper tool” would be a dowel. Determine the correct dowel size for the holes on the bottom of the case (these were paradoxically easier to drill than the top-mounted screws). Anyway, if you drill through the center of the dowel (which should extend just beyond the top of the holes), you have a jig/guide/etc. It would help the process. Anyway, I used a 1/16 drill bit (smaller is better… but needs to be a size that works with the screw extractor). Don’t “go cheap” on the drill bit – and be certain to use a metal bit (one of the “fancy” coated bits is appropriate, here, as it takes a while to start the hole).

17 January 2012

I confess I still had a tool from Dave H. on my workbench. It was a short, drilled-out bolt with a 1/4inch drive hex socket as its head. The large head prevented the bolt from reaching the deeply recessed screws in my machine, so I put it aside. Today I got motivated to try grinding down the bolt head to fit into the recess, and this is the result. It fits into my old machine!

18 January 2012

Peter N. of Wilmington, NC, the Jura Capresso Doctor, wrote me a long note about

the stuff he sells on eBay for repairing these machines

http://myworld.ebay.com/juracapressodoctor/

I just read your log about Nespresso machines at ..

I’m the “flea-bay” guy you mention :)

Let me give you some more history/input on this, as there is a lot to say:

$40 cost: The aluminum oval head tool was originally imported by me from Germany. The German sellers charged close to $20 for the tool, and a whooping $30 for shipping (!) and to add insult to injury, they refuse to ship to USA, so I had to have the tools shipped to Finland first and have my friends ship to USA adding further shipping costs. At the time I ordered only 4 at a time (due to the cost, and since I did not know if I was going to be able to sell them). Hence, the $40 cost.

$20 cost. After selling a few of the German tools, I decided to see if I could have somebody make them for me. It was expensive to have them made in small quantities, but I eventually found a company that made me 200 of these for $6/each. This is when I dropped the price to $19.95. The markup may seem big, but this tool was originally intended for Jura-Capresso superautomatic owners that must pay Capresso a fixed price fee of $235-$350 to get their machine repaired, and from previous sales I found myself spending a lot of time helping people diagnose problems with their superautomatics.

Unfortunately the first batch of aluminum tools was not very strong (as you note in your blog). The first batch of 200 tools was made to my technical drawings, and the manufacturer apparently was not able to follow it perfectly. This resulted in the tool not sitting tightly enough around the screw head and I had to tweak each tool manually (what a chore!) to make them work. While it worked, it was tedious and the tool was admittedly not very strong. I was ready to give up on this, but last summer when I ran out of tools, I decided to contact the manufacturer and see if they could make the tool and guarantee a perfect tight match with the screw head.

Frankly, I never realized that there is another market for the tool, that does not involve the complicated and overly expensive super-automatics! Had I known that, I would have listed the tool for $9.95 a long time ago and I will definitely make sure to put up a specific Nespresso listing that I continuously will keep at a low price ($9.95 / free shipping or lower).

Peter was kind enough to send me a pair of sockets and screws. I’ll send one to the next person who joins the queue.

19 January 2012

Today an Irwin #8 spanner bit arrived in my mail. As you can see from the picture, the gap between the prongs is simply too small to fit around the oval-head screws that were in my old Nespresso machine. But the #8 has worked for some (see above) so your mileage may vary!

31 January 2012

Mr. Arenas of Barcelona wrote me about his adventures at Ikea, adjusting the bolts and repairing his machine:

This morning I went to the Ikea Store, customer service area. I showed them the photo, asked me where it belonged to, I said I was not sure because I was doing a favour to a friend. They asked a guy from the warehouse to come over and see, he had a look at it and asked me, “how many do you need?” I said 4 units and in 3 minutes I had them for free, at no cost!

It’s just perfect that these bolts have a Philips head, in one hand, you don’t need to attach the bolt to another piece in order to make a handle. In the other hand, the Philips head allows you to use all the force/power you need to unscrew the limed stuck screws. And finally, this bolt perfectly fits the hole for the “Radio shaped” Nespresso type machines like Krups XN2001, etc.

Tuning was made with some robust pliers. I pressed each bolt following the way of the slot in the bolt. This way is easier for the user to know where the narrow part of the oval head is. I pressed each bolt half way in the plier, otherwise it can’t be pressed, it’s too hard (or I’m not strong enough!) Once each bolt has been given the desired shape, I used this other plier to lower the inner part of each bolt, otherwise it would not perfectly fit the oval-head screw. Also, I could have be used a Dremmel instead, but once again, I did not have that “so necessary” thin drill.

Philips screwdriver is a MUST, otherwise the head of the bolt will be damaged. If a short Philips screwdriver is used, then it’s much better because it gives you a much better control. When using this bolt, you must press it very firmly against the oval screw with the screwdriver, and do slow wrist rotations, relaxed, just like if you were opening a safe, otherwise the oval-head in the screw may be damaged, and the whole thing would turn into a big problem.

Typical lime in the button board after 6 years of daily use. Needless to be said that I cleaned it with some cotton and alcohol. Yeah, I had an additional problem. The board was dirty, but the conductive part in the sillicon button was completely gone, so after cleaning it no way I could switch on my Nespresso! Ok, in order to bypass this situation, I used a piece of aluminum foil and glued it to the button. This is just temporary, but it works.

I changed all visible screws in my Nespresso machine (10 in total). I DO recommend everybody do it. This kind of oval-head (in the screws) will go on getting spoiled each time they’re screwed-unscrewed. These type of screws were created as a protection for appliances, but as a screw in itself, they’re not efficent, and when unscrewed, they should not be used again.

Mr. Arenas kindly made extras for others to use!!

8 February 2012

One of Mr. Arenas’ sockets went to Bruno T. in Lisbon, Portugal and he wrote me to report an easy victory:

Just got the tools from Mr. Arena and in 5 minutes got my problem solve :). Please confirm that it’s to send it back to you or you have someone new in queu.

Bruno also pointed out that the circuit board can be removed without pulling out the rubber button.

10 February 2012

Well, this is a first :) Lee A. of Brooklyn brought his Nespresso machine all the way to my place in New Jersey, and using one of Peter N.’s sockets we opened it quickly. The screws could be turned pretty easily with just the supplied key ring, but we soon switched to turning the socket with a regular screwdriver-type tool holder for a bit better control. His machine is modern and has a regular toggle switch at the back to turn the power on and off, but still uses soft push buttons to start and stop the pump. Anyhow, the easy part is over; now Lee has to hunt down an elusive internal leak.

12-12-12

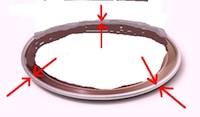

Lee wrote me about his adventures in replacing a leaky plastic elbow joint, which is circled in the picture on the right. The two wide, flat openings on the side of the joint are for retaining clips that grab the O-rings inside:

My apologies for the extremely delayed response! Here’s the final result of my Nespresso project. I coated the broken one with epoxy and duct tape and it temporarily fixed the problem. Then Peter ordered me a replacement part which he then had to wait many months to receive. I put on the part but there was leakage problems so he sent me some replacement gaskets and some kind of water sealer/lubricant which I put around the gaskets. Now everything is fixed.

14 February 2012

First repair in Africa! Patrick d’H. in sunny Cape Town, South Africa opened his machine using the old steel bolt that I ground down so it would fit into the plastic wells on the bottom. Maybe a reader can help him, because I do not know the answer to his question:

The issue I had was the following: it was starting normally (warming up). As I push the pour button, after one second it switches off completely the machine. Would the problem comes from the switch?

25 February 2012

While goofing around at the workbench this afternoon I experimented with cutting a slot into the head of an oval-head screw. I used a dremel tool and a thin cut-off wheel, it was a bit of a challenge to hit the middle and keep my hand steady. I think the result is pretty good: a small screwdriver fits very well in the new slot. If you have to work on one of these machines, this can save you the hassle of running around to find replacement screws, and it will be easy to reopen the machine!

28 February 2012

Robert S. in San Diego, CA sent me this report about repairing his Nespresso Model C machine.

Babka and Duka could not use their Nesspresso machine. The symptom was the power on and off button took more and more pressure to turn on the machine. The fix was to wipe both pieces of the switch with a clean Q-tip with 91% alcohol. I wiped both on/off and start/stop since I had it open. I replaced all 8 screws with stainless steel #5 Phillips Pan Head screws 1/2inch long. They can be ordered from McMaster.com if they are not available locally.

Robert, Nesspresso cafe lover, Nesspresso security screw non-lover!

10 March 2012

Wim B. in London, England dropped me a line about using the old steel bolt:

I did indeed receive it; opened the machine and only had to clean the sensor with a piece of cloth and it worked again. Changed the screws for normal ones and we’re very happy with it.

3 April 2012

Donnchadh M. in Hasselt, Belgium sent me this question about her machine:

I recieved the opening tools today and got my machine open, thanks a million. .. The machine itself has problems pumping water when theres a capsule inserted but flows freely when theres nothing inside. I cleaned everything and reseated all pipes but still seem to be a weak flow so i am not sure what the issue is?? But at least i have it open and we can see further if theres a fix.

11 April 2012

Dave W. from Lake Worth, FL wrote me with some advice for using a screw extractor to remove oval-head screws:

After Nespresso told me it would be $125 to repair my C90 I started googling, and I found your blog. An hour’s work with a drill and a screw extractor, and I had the machine open.

For the screws in the shallow holes I just used a pair of small pliers, and was able to grip the screw heads. I wasn’t able to fit the pliers into the deeper holes, and had to use an extractor.

I used the smallest screw extractor I had. I believe I got it at Harbor Freight, but you can also buy them at Sears and most hardware stores. They come in sets. Normally you use a left-handed drill bit to drill the hole, and often the drill bit itself will bite and spin the screw out, but I had broken my 1/16inch left-handed drill bit, so I used a regular right-handed one. Because these screws are in there with such low torque you only need a very shallow hole for the extractor to be able to get a bite and turn the screw out. In the attached photo you can see the drill bit, the extractor, and a screw with a very shallow hole in the head. I used a cordless drill and a steady hand.

I cleaned the switch, and the machine worked perfectly! Eight #4 panhead screws and it all went back together. Thanks so much for this resource.

15 April 2012

Jorge S. from Lisbon, Portugal says:

Here are a few pictures of the stripped down Krups. Unfortunately I don’t think I was able to solve its issue, as even after a full check-up and cleaning it still resists to warm-up, the leds keep blinking nervously when we turn it on… Maybe it’s just time for a replacment.

1 May 2012

Fausto P. a.k.a. MrWho from Coimbra, Portugal wrote me to report:

I’d like to thank you for sharing your tips on opening up a Jura (here it’s a Krups) Nespresso Machine. I succeeded using the melted BIC pen trick - worked perfectly, cleaned the power button and closed it up again with normal philips screws. Not bad for a €10 machine I bought from a friend who replaced it with a new machine.

7 May 2012

George C. in Honolulu, Hawaii wrote me this note:

Aloha. Received the magic socket from Jorge in Portugal on Saturday. Spent Saturday afternoon dismantling my machine and chasing down the leak, which appears to be coming from the extraction unit. I suspect the tiny little red washer, although it appears to be in fine shape. Note that as others have mentioned the original machined bolt no longer grips the sides of the oval screw heads, but the “keyring version” works perfectly.

6 August 2012

Dave W. from Lake Worth, FL wrote me again, this time to explain how he replaced the recalcitrant soft-touch button in his Nespresso C90 with a more reliable button:

I wrote back in April to say I had used a screw extractor to fix my machine. After a few months it began to fail again, and the time between wiping the power button got shorter and shorter. So I replaced the button with a real button. Search for “B006WRNTA8” on Amazon, to see a SPST momentary push button switch that fits right in the hole of the C90. I unsoldered the original circuit board and rubber switch, and soldered in the button. Now it works great, every time. See attached pictures.

6 September 2012

David A. from Atlanta, GA sent these directions for unsticking a stuck check valve.

My machine was not priming, so no water would flow from the tank to the rest of the machine. The pump is a simple diaphragm pump, with check valves to make sure the water only goes in 1 direction. Think of the check valve as a cap at each end of the pump with a spring to hold it in place. When the diaphragm is pushed in the flow direction, the water pushes past the caps (and the springs compresses a little bit). When the diaphragm moves in the non-flow direction, the caps prevents the reverse flow of water. In my case, the input cap was stuck. Unfortunately, the pump Nespresso uses can’t be disassembled, but there is a workaround.

To repair a stuck input check valve:

In addition to the screw removal tool (I used a spanner bit), you need a bamboo skewer (see photo) or something similar. Remove the two screws from the bottom of the machine holding the left gray cover on. Pull the bottom out, the top of the cover it latched to the machine.

There is a yellowish clear tube running from where the water tank sits to the input side of the pump. Pull it off.

Insert the bamboo skewer and push gently to depress the check valve.

Put the tube back on and test. If you have success, reassemble the cover.

26 October 2012

Fellow New Jerseyan Paul S. of Randolph stopped by my place to grab a socket in person. He sent me this note about restoring marital bliss :)

Thanks for the use of the tool. I opened my C90 up no problem. I cleaned off the connections on the power switch with an eraser, and replaced the “screws” with #4 1/2 inch zinc screws, which fit perfectly.

Everything seems in working order now and my wife can finally turn the machine on by herself.

12 November 2012

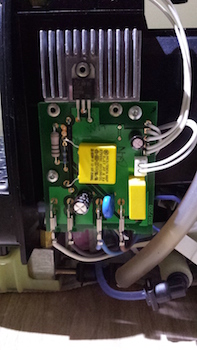

Enzo from Turin, Italy reported his success with repairing a malfunctioning machine by replacing bad capacitors. He writes:

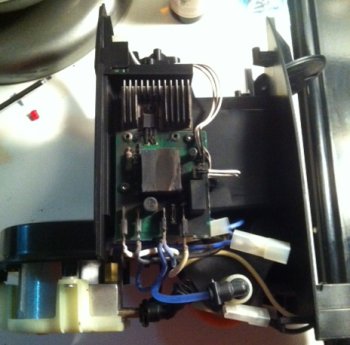

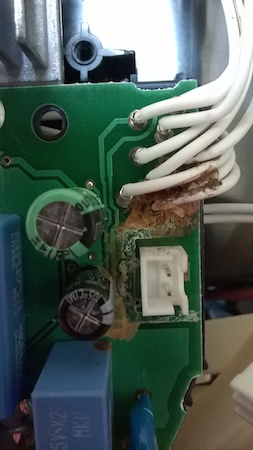

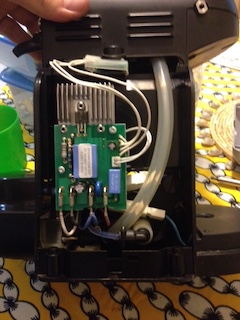

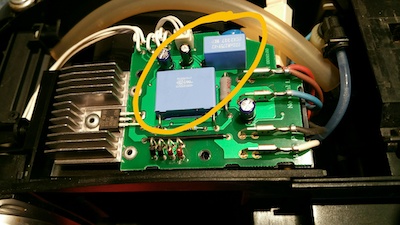

I’m writing you from Turin (ITALY) because I think it could be usefull for your blog readers to know how to repair their Nespresso coffee machine when it doesn’t works because of the “mad blinking” like happened to Jorge S. from Lisbon, Portugal (15 April 2012 post). I had the same problem and I totally fixed replacing two capacitors (the blue squared capacitors) on the circuit board. It seems that this capacitors are used as filter for the main supply, but after a while they have some loss and the machine LEDs begin to flash quickly and there’s no way to prepare a cup of coffee… It will cost a couple of dollars (even less) and the machine it will work like a new one!

The replaced capacitors are the two “blue boxes” in the picture. The value of each varies from machine to machine (every make use a different one… here in Italy we can have KRUPS and De Longhi machine) but is printed on every capacitor. In my case (KRUPS XN 2105) one was 220nF (nano Farads) and the other was 680nF. Pay attention to use the same kind of capacitors (X2 MKP 275 VAC).

24 November 2012

Susy P. in Vevang, Norway opened her machine only to discover that the pump had failed, and the price of the new part was ridiculous. She reports that she jumped at a deal from Nescafe - buy 15 boxes of capsules and the machine is free! I’ve never seen that sort of offer in the U.S.

30 December 2012

Mário P. of Portugal sent this advice for making a tool from a plastic pen shell:

Found your blog entry through Rolfje blog and solve my Krups XN2001 buttons problems in a hurry! I’m just writing to show you the solution I made after trying the first time with the BIC pen… So after unscrewing just two screws it was broken… The platic walls were thin and with little effort they brake.

So, using a soldering iron I heated the front of the pen and spread the melted plastic to block the pen so it would have a lots of plastic on the top. After, with the plastic moldable, I press it on top of a oval screw and let it cool off.

This way I managed to get a stiffer socket that has the exactly shape of the screw head (picture attached).

Thanks for this awesome compilation!

Stories in 2013

6 January 2013

Cathy L. of Phoenix, Arizona easily used a plastic pen case to remove a set of oval-head screws:

I was able to remove the oval screw from my Krups Brewmaster Jr. 170 by using the BIC pen method. I didn’t need to heat the pen. I just used the tail (non-writing) end with the plug removed and pressed it firmly against the screw while I turned it. Now, on to fix what appears to be a pumping problem.

7 January 2013

Jose L. D. D. of Barcelona, Spain hit the all-too-common problem of a dirty switch that prevented his machine from turning on, but his machine has torx screws in the base. I don’t know whether Jura is giving up on the goofy screws, or if the factory just ran out that day and substituted whatever they had. Anyhow here’s the picture.

20 January 2013

Andrea W. in London opened her machine with the well travelled socket and cleaned her machine’s troublesome switch.

30 January 2013

Michael K. in Miami, Florida wrote me a sad story about mold in his Nespresso C-100.

First of all thank you for your effort in keeping this blog up. Being only semi-handy I look to the net for advice like this. Great job. I returned from a few months away to some absolutely disgusting coffee and a moldy smell in my machine. Descaled twice, flushed with boiling water and baking soda, boiling water and vinegar and lots more boiling water. No luck. Two calls to Nespresso (total of 40 minutes on hold) to be told there was nothing to do with a 4 year old machine but replace it. Ordered a new one. Got it. Still curious about my mold problem so I decided that even if I had to break it open I wanted to discover the problem.

FOUND YOUR BLOG- THANK YOU.

The melted pen worked on all but one last screw so I broke the last side panel off and started unscrewing everything I saw. When I yanked the front nozzle off I found the problem. YUK!!! Not very happy about the last few coffees I drank anyway. YUK, YUK!! I’m certainly not an engineer but as far as I could tell from looking at the construction of the machine there should not be any water where I found the mold.

You can call this one a success since I got it open (beat the evil oval screws) and discovered the problem. This was more of an autopsy rather than an attempted repair. I can’t imagine how long the hold time with Nespresso will be to make a complaint, considering I waited 20 minutes to buy a new $200 machine.

By the way, if you are replacing an older machine they give you a $49 discount. Only found this out on the second call- the first person didn’t offer it.

2 February 2013

Jose L. D. D. of Barcelona, Spain wrote me again, this time about a second repair that he performed. I think he is now an expert :). And I quote:

A relative brought me to learn yours, with the same problem, so I tried. But if wearing this special screws.

I’ve got no problems but in a different way to explain what has happened and how I did it.

Once again I remind you that I use the Google translator, so if something does not understand or is not clear, let me know and I repeat it without any problem.

I go:

The first thing I noticed is that the screws are different. Displayed on your site about the oval measuring 5 mm x 6 mm, but this machine has an oval 4mm x 3mm.

I’m not counting the failed tests I’ve done, but what inspired Mr. Arenas explained as he tried to do, with a screw IKEA, but it was great for my screws.

Then I remembered that I had around a brass tube inner diameter of 5mm and decided to try that. Just squeezed with pliers to shape and within minutes I got.

The only problem is that as the tube is 5 mm, the oval is left is 6mm x 3.25 mm, but just press a little “side” to use it and that’s it. I send you a picture for you to understand better. Ideally, keep trying until you gradually adjust

Not quite perfect but made in minutes and above …. works.

The brass tube I bought years ago at a store of aeromodelling.

3 February 2013

Martin G. of London, UK wrote me a nice note about his success in repairing his machine.

Thanks for a fantastic blog!!

As you might have guessed, my machine broke down today, and I was stuck on how to open the thing up. My M 190 Magimix nespresso machine had just stopped pumping.

I decided to make my own tool - so I used an old Ikea spacer (as you said), and it worked! Then it was only a loose tube that needed reseating. Success! Only cost me an evening fiddling around. The hardest thing was squeezing the Ikea spacer into just the right shape.

I can’t believe they put these screws in!

14 February 2013

Shai A. of Herzeliya, Israel (first socket visit to Israel!) wrote to say that he opened his machine with the socket but has not yet found the problem.

16 February 2013

Alex F. of Saint-Martin, French West Indies sent me a note and a picture about his experience repairing his machine, which seems to have a burned-out part on the board.

I woke up this morning and my nespresso C90 didn’t want to come on. When I shake it, I could ear a part that was disconnect. Thank you so much for your blog!! I made the tool with the bic pen first. It was good for the 6 oval screws below. When I saw that the red switch was in perfect condition, I decide to open the rest to see where this little round part was coming from. To unscrew the 2 oval screws from the top, I fabricated a spanner screw bit out of a regular flat bit by cutting with a grinder. Then, I pull out the plastic cover in front of the main board, to realize that it’s completely burn.

I don’t think it worth replacing it. I will still look to see if I find one on the internet.

4 March 2013

Oscar M. of Portugal sent me a picture and this short note about his Krups machine:

Thanks for your blog. I opened my NESPRESSO in 5 minutes, cleaned the power button and reinstalled the button rubber. I’m another Portuguese using the melted plastic pen.

19 March 2013

Alvaro G. of Malaga, Spain sent me a note about blinking lights on his Delonghi machine that refused to make coffee, including YouTube videos showing the symptoms:

The problem? My Nespresso is not a KRUPS, it’s a Delonghi model EN 95.P. It’s similar to the referred by Diana T in the 24 November 2011 quote. But mine has two green buttons (small & big) and the on/off is on the back. My problem is the blinking green lights, not the “dead” on/off button (that I don’t have in the same place… )

Videos showing the bad symptoms:

Video 1: http://www.youtube.com/watch?v=gJopqKtR85c

Video 2: http://www.youtube.com/watch?v=uMcUcWyleIs

Video 3: http://www.youtube.com/watch?v=cF6QkJ_JEfk

28 May 2013

Alvaro G. of Malaga, Spain wrote me again with happy news about his machine:

Thanks to Enzo of Turin (update 12 Nov 2012) for directions and email help! Less than 3$ fix !! I replaced both capacitors on the machine board. The big one is rated 680nF and 275 volts, marked “680nM275V-X2” and “PCX2337 MKP”. The small one is rated 220nF and 275 volts, marked “220nM275V-X2” and “PCX2337 MKP”. Both found on eBay with that information. Also available on Aliexpress.com but at a higher price. So thats it. Before blue color. After yellow.

The seller shop from where I bought the items (10 piece minimum) is

http://myworld.ebay.com/2012topdeal

and I have 9 of each

available … if someone needs them I’ll be glad to give them away :)

Video Working machine again: http://youtu.be/mj8E97SQ1Og

29 May 2013

Received a stainless-steel socket from Peter Nielsen. He wrote:

I finally got my supplier to manufacture the tools in nickel-plated stainless steel! It required a big order and investment, but at least I can now supply proper tool bits the way I think it should have been done way from the start. These are going to sell for only $3 more, or $12.95, and will probably last “forever” unlike the $9.95 aluminum tool that sometimes is toast (or at least requires adjustment with pliers or a hammer) after a few uses.

It would be great if you let at least one of the tools circulate so that we can see how long-lived the steel version is. I expect it to last a lot longer than the aluminum version.

13 June 2013

Mark S. of Metuchen, New Jersey used the new steel socket to open his Nespresso professional (!) ES80 machine, which was having flashing-light problems. There’s a picture of the very long oval-head machine bolt he had to remove. Mark wrote:

I was able to extract all but 2 oval screws. Try as I may, I couldn’t get 2 of them to turn without the driver slipping off. Still, the last two are inside and underneath the bottom plate. There may be enough room for me to get a small vice-grip on them to get them turning. If not, I may drill and extract them.

I think I found the pump, but it doesn’t appear that I’m able to descale its insides. I may have to re-assemble it and resort to again following their ineffective descaling instructions. I have to descale the thing every 2 weeks. It has not been properly descaling. I go through the descaling process, carefully following the instructions. The flashing descaling lights then re-set, but start flashing after 2 weeks, and the coffee begins to taste bitter, again. I know it’s not defective lights, because when the lights flash, the coffee also begins to taste bitter. After descaling, the coffee is once again, smooth and full tasting.

I thought that by taking it apart, I’d be able to descale the inner tank, etc. Turns out there may not be an inner tank. The pump may be also the heating chamber. I may have to find a way to get inside the pump.

20 June 2013

Ted V. in Thunder Bay, Ontario used the latest stainless-steel socket from Peter Nielsen to open his machine and sent this note:

The tool arrived today (thurs, June 20). Machine opened with ease

Found the cause of the leak. A cracked coupling. Has anyone ever had this problem? Can I buy a part? In the mean time I experimented with a few epoxys and couldn’t get enough strength. I took a washer and epoxied it to the face of the cracked/repaired connector. It seems to have given me enough strength. I still may order a new part as security. I also used different screws to put the machine back together.

Update 18 August from Ted:

My repair job on the coupling didn’t work but Peter the nespresso doctor sent me a new part and my machine is working great.

25 June 2013

Christophe M. in Toulouse, France fabricated a bit to open his Krups XN2120, and then repaired it with capacitors from Alvaro G.! He explains:

I found your blog a few days ago while looking for information on how to open Nespresso machines ; and especially their very odd screws. For the record, I tried the bic trick that worked for 2 but my hapiness stopped when I melted th pencil badly in the third cavity. I then decided to for something I can easily do with what I had. I came up with another variant of the tool (I attached the picture, as I’ve not seen something similar). It’s made out of a standard bit , nearly plain octogonal, in which I grinded a slot of about 3mm (damn, you’re probably in inches so the shorter dim. of the oval).

Update 24 July from Christophe:

A quick word to let you know that my machine is up and running again :-) Thanks to your blog and especially to Alvaro whose capacitors are doing a great job !!

21 August 2013 Ray K. from Denville, NJ wrote to ask

for advice on diagnosing his machine’s pumping problem:

From another Jersey boy.

I have a D300 which I put into storage in my cellar about 5 years ago when I got my first Keurig. Did not have room for both on my counter.

My interest in espresso machines was recently revived. I brought it up from the cellar and was unable to revive get it to pump water, even after calling Nespresso. They no longer sell or repair this great model. They few tricks they had me do were to no avail.

So, being an engineer I was determined to get inside the machine and see what was wrong. I was really stumped by these oval looking screws and searched high and low on the internet for help. I finally came across your blog after googling “nespresso tools.” At last – some enlightenment as to how to open the machine. Bought the key-ring device from Neil of ebay for $12.95. It worked great.

I ordered the machine and now am stumped. All connections are solid and the hoses are tight, but the machine will not draw water from the reservoir. It stays in the first few inches of the clear feed tube. There are lots of hoses, some for the stem operation.

11 September 2013

Craig S. from Rimini, Italy sent along his success story about repairing his machine’s pumping problem:

I found your blog whilst searching the internet for advice on fixing our Nespresso machine. Thought you’d like to know that I managed to open it up using the BiC pen method that a couple of your readers had suggested. I couldn’t believe how easily the melted pen unscrewed the very first oval screw on the machine, but then the plastic of the pen broke on the second screw. Pen number 2 broke quickly as well, but by pen number 3 I had gotten the ‘knack’ and managed to dismantle the machine no problem.

I fixed the ‘water-not-drawing’ issue by forcing air and then water into the drum thing (which I assume is the pump) via a syringe. See attached photo. Fortunately the point of the syringe fitting perfectly into the rubber seal and I first forced air in which cleared the opening. They I pushed in water and then pulled it out again using the syringe. Did this a few times. All working fine again now and my Wife can now take the machine to her office, which is why I dragged it out of ‘retirement’ in the first place.

23 September 2013

Jonathan L. from Los Angeles used the steel socket to open his D290, but a solution to its blinking lights eluded him:

Here’s a pic of the D290 circuit board. I tried replacing the blue and white caps but neither fixed the problem. It still either flashed all lights during startup or just wouldn’t start up at all. Thermal fuse passed a continuity test. Giving up and either buying a used D290 on eBay or upgrading to the Delonghi Lattissima Plus. But glad I gave it a shot!

26 September 2013

Markus H. from Mainz, Germany sent in this advice about repairing Nespresso buttons:

I find it worth mentioning, that The black paint at the back of the silicon buttons is graphite. I used graphite spray to renew this and the buttons worked like a charm again.

10 October 2013

Frank van B. from the Netherlands sent me a note about sources for information and parts:

I found your Jura blog when I did a search for a Krups Nespresso eachine and I enjoyed reading the whole thread from 2010 on, it’s great and much appreciated ! Since the patent has expired the Nespresso cup machines have become more popular in Europe as now coffee cups from other brands are available and often way more cheap as the Nespresso ones, some of these newbie coffee cups do very well here.

I’m from the Netherlands and find it a challenge to solve problems with goods that seem to be designed to be replaced after (minor) errors and the Nespresso coffee machines are one of these, a repair costs at least 75 euro and at that same price (or even less) a new machine can be ordered online, what a waste of money and good materials that is as they mostly end up in the rubbish !

During my searches for parts and manuals I found a couple of interesting sites and for the blog this English source is a good start for parts and a workshop manual that few have access to:

http://www.buyspares.co.uk/krups/coffee-makers/catalogue.pl?shop=krups&path=561166

9 November 2013

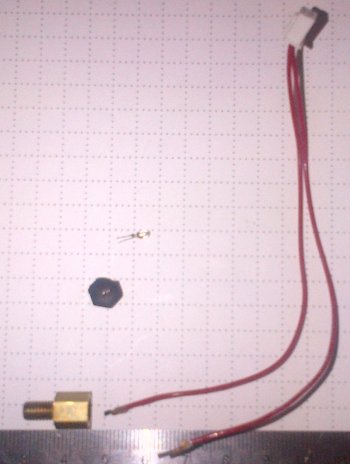

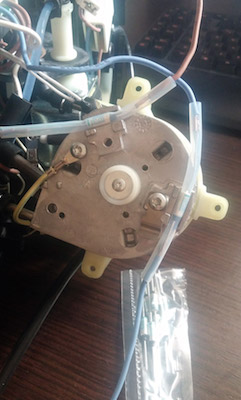

Cam B. from western Canada sent a picture and story about a failed temperature sensor:

I am dealing with a [flashing lights on machine] issue at the moment. What I discovered in my unit (careful application of the #10 spanner got mine open) was that the epoxy holding the temperature sensor in its brass housing (threaded into the thermoblock) had expanded over time and broken one of the wires.

See picture. That little glass bead is the actual sensor. It was potted with some epoxy into the brass housing, which was then threaded into the thermoblock/heater unit in the machine. It looked like the epoxy had expanded over time, and in doing so had broken one of the wires to the sensor. I guess the way the controller works is if it doesn’t ‘see’ a temperature change - hard to do with out a working sensor - it shuts the unit down and blinks an error code.

Working now on trying to source a replacement part. Lots in Europe apparently, but the 52euro shipping is a bit of a pain.

Thanks for putting this info together. I found a similar site in France where ‘magimix m200’ users were sharing repair stories. They had electrical and water flow diagrams as well. People really love their coffee, I guess.

22 November 2013

After six weeks en route the steel socket finally reached Ricardo V. in São Paulo, Brazil who wrote:

Look at the beautiful thing that just arrived (“Just”). Customs + Post here s**ks ..

Here’s some photos, after the long way traveled by the tool. Thank you so much, I’m still trying to believe this internet power.

28 November 2013

Kelly B. from Fremantle, Western Australia shared a picture and story about repairing her machine:

Thanks for your Blog. It inspired me to make a tool out of a split pin. It was nice and soft so easy to drill out. My supervisor tried to get a tool and we’ve waited for weeks. Now I can replace the damaged cord and get it back in use. Thanks.

28 December 2013

Jean-Paul G. from Dampierre en Yvelines, France made his own socket and sent me a picture of it:

Today I had a very good read at your topic on this subject. I had dismounted my Krups XN 2105 a few weeks ago. I did that by using a bolt in which I have drilled an ovalised hole. It worked pretty well. However I had not diagnosed the trouble I was facing, as the machine had been working in an erratic way. The green lights were blinking but sometimes I was able to make a cup of coffee. I tend to believe that the capacitors could be causing the troubles as explained by Enzo of Turin and Alvaro G of Malaga. I understand Alvaro G still has capacitors to offer. Could you please pass him my email so that we can be in touch.

Stories in 2014

4 February 2014

Pierre V. from Belgium sent me a picture of his Magimix M100 circuit board with a burned capacitor, unfortunately I had no answers for him.

My name is Pierre and I mail You from Belgium. Thanks for Your blog about repair a Magimix M100, it was really helpful. I have an other question : I open the machine and pull out the electric print, and there was a piece burn out, know You the value of this piece so I can replacing? I put a photo with. Is It also necessary to replace the two resistors (blue) and above all what can be the reason of this defect?

23 May 2014

Sasha L. from Israel wrote me to ask about a part:

Thank you for repairing blog of JURA coffee maker. I bought this Oval head key Repair Tool ant it is perfect and cheap: http://www.ebay.com/itm/Oval-head-key-Repair-Tool-for-Jura-Krups-AEG-Nespresso-/181305075389?pt=Small_Kitchen_Appliances_US&hash=item2a369fe6bd

maybe you can help me with buying this part which I can’t find… or maybe you can tell me which wire goes to the switch and which to the led?

25 May 2014

Onno M. from The Netherlands dropped me a line about his experience repairing his recalcitrant Nespresso buttons – remarkably similar to mine :) – and I’m happy to add a link.

http://www.glowbug.nl/oddsNends/KrupsXN2001.html

3 June 2014

Dušan M. from Brno, Czech Republic completely reworked his ES 80 machine’s switches and sent me details about the result.

thank for many helps of your site.

My story : To first is thermosensor failed. I make new with NTS 100 kohm/25C. By repairing i make shortcircuit and circuit board fired up.

Now i had free hands to make anything…. I going back in to years 1990’s and make the Nespresso with “hand steering “. Only new pieces :

On-Off button for 1. heat circuit with thermostat 90 C

Control light

On-Off button for Pump/Kofee

On-Off buton for 2. heat circuit with 120 C Thermostat for steam

It’s all. Now is machine ready for long, long time.

23 June 2014

Brenda C. from Chicago reported success with her repair of a Citiz+Milk:

First of all, thank you for posting all of your repair stories to your blog. I would have never attempted to fix my machine without reading everyone else’s experiences. I can’t stress enough my appreciation.

Here’s my update:

A friend of mine was going to toss out her Citiz+Milk machine and I took it instead to see if I could do something with it. The espresso machine made noise like it was working but it was leaking from the bottom of the machine. Nothing was coming through the top. I started my project to locate the leak by trying to take it apart. I found your blog immediately when I attempted to get those evil oval screws off to no avail. Wow. Was that annoying.

I used the bic pen trick and three pens later I got all the screws off. I manhandled the rest of the machine to get to the guts of it and found 2 parts totally cracked, the “elbow fluid connector” AND the “air valve apd cpl mount” (the air valve is pictured below). Here is some good news and bad news: Both parts are available in the UK via buyspares.co.uk and partsmaster.co.uk (yea!), the elbow is available for shipping to the USA, HOWEVER the airvalve is ONLY available for purchase by EUROPEANS (wha???). Seriously. In my case, I have a friend in the UK, shipped the parts to her and she brought them with her to the US on her last trip home and delivered them to me. (Yes, I know this is impossible for most people, but I wanted to share this story anyway). I tried to find a work around to get something shipped over here, but I never found an option other than the “I have a friend in europe” scenario.

I replaced the parts and threw out the other ones, but still had a leak. Turns out that each part has an o-ring at the connection (some red, some black) and I didn’t see one of them attached on the damaged part and I threw it away without checking closely. That was pretty dumb on my part. Instead of paying $15 to ship an o-ring from the UK, or wait until Christmas for my friend to come back home, I found a replacement at HomeDepot (pictured below). HomeDepot did not have silicone o-rings (I think silicone o-rings are red and are more high temperature resistant), but so far the regular black rubber is doing the job on the elbow connection, also, the size should be metric, but the imperial ones fit fine and are not leaking. Lastly the #4 sheet metal screws to replace the Evil Ovals works very well also.

All fixed, not leaking, and delivering delicious coffee!

To sum up:

Pro-tip: Hold onto all damaged parts until you are absolutely sure you’re done with them - inspect all damaged elements for additional working parts that you might need.

THANK YOU AGAIN!

21 July 2014

Joe M. from cyberspace sent this note:

I was just looking through your blog on deconstructing Nespresso machines, and just thought I’d let you know that I’d had great success using a Dremel with a thin cutting wheel, and just converting the screws into flatheads. It works well, and allows for reuse without having to replace the screws. If thin enough a file could also be used.

9 August 2014

Demetrios B. from Cleveland, Ohio sent this question that I was not able to answer:

I have a Nespresso D290 machine that has served me admirably for several years. 3 days ago the yellow light began blinking and the machine would no longer brew. After several attempts of pushing the on and brew buttons simultaneously I was able to get the machine to power on and I descaled the machine. It worked for the rest of the day but was making an intermittent clicking noise. I turned the machine off, but have not been able to get the blinking yellow light to stop. .. I have partially disassembled the machine and the capacitors look good. I would like to test the thermal fuses but coul use a real disassembly manual. Can you help?

27 August 2014

Luke R. in Auckland, New Zealand wrote to borrow the socket and get capacitors:

I have stumbled across your blog on the Jura made nespresso coffee machine! I have a flashing light issue where the lights blink continuously and I can not get the machine to respond to anything … Now I can’t for the life of me remove these screws and I was wondering if there was one of tools floating about that could be posted to me here in New Zealand? … Also Avaro mentioned he had some capacitors available, how could I get in contact with him?

Ricardo V. sent the socket and Alvaro G. sent capacitors, thanks guys for your quick responses! After a long, long trip down under, on 28 September Luke wrote again:

The socket arrived this weekend! I have now opened my machine and much to my delight their was no water damage in sight! … I am now trying to work out the issue, I have 2 thoughts, possible air block in the system ( but then again this wouldn’t cause my lights to blink) … Orr the capacitors, so I will await their arrival and get them changed!

On 18 November I got the good word:</P>

This is perfect timing, after a long wait on parts I finally fixed up my nespresso this Sunday and all is back together! I shall post the tool on to Chris D in the UK tomorrow morning and will also send over my before and after shots of my fix to you Chris L! I will also include the two capacitors that i replaced on my nespresso machine with similar flashing light issue in a hope that this speeds up Chris D’s repair. (very easy soldering jobby).

29 August 2014

Vic from cyberspace shared instructions and pictures for fashioning a tool from an X-acto knife handle:

I fashioned the tool from an X-acto knife per instructions found on your blog. I enclose photos. I was able to open the C90 and test it. Found no obstructions impeding water flow so conclude that the pump must be failing. Importing a replacement pump from Europe would have cost more than the $99 Inissia from Nespresso. So I bought the Inissia. Their service department was very helpful and tested the unit with me over the phone. They came to the same conclusion. Their recommendation, surprisingly, was to keep the unit since it still worked but just took longer. I bought the new unit anyway; I didn’t want to run the risk of being without my espresso for a number of days.

Here are the steps I followed in making the tool: Use an xacto knife with a slim handle. It must fit into the screw hole. If the tip of the handle is curved, file it down flat. It helps to use a vise. See photo. Drill a 5/32 in. hole in the center of the handle–mine was not exactly in the center; no matter. It helps to use a C-clamp and a drill press. See photo. Use a hammer and tap lightly on one side of the hole and then the other to change the shape of the hole from a circle to an oval. See photo. Test the tool. If the fit is not right keep hammering a little at a time until the tool fits. Don’t try to adjust too much at one time. Be sure to remove the blade before using the tool.

3 September 2014

Stefanos in Athens, Greece sent me a happy story plus a picture about repairing his madly blinking machine:

I came across your blog about repairing the Jura Nesspresso coffe maker and decided to give it a go when my machine started suffereing from “mad blinking” and couldn’t use it for some time. After removing the oval screws, I followed Enzo’s (from Turin) advice (update November, 12th 2012) and repaired my NEspresso coffee maker.

Thanks for the very helpful blog and special thanks to Enzo for the solution to the problem.

14 September 2014

Szilveszter P. in Budapest, Hungary dropped me a line about his success in making a tool and cleaning his machine’s on-off button:

Thank you very much for all the information on your blog about repairing a Nespresso machine. I had the same power button problem, and successfully fixed it, with the help read on your site. I wanted to fix it right now, so could not wait. My solution was using a cocktail spoon I found in my kitchen right after I gave up fixing it right away, and some flat wire. It worked for me, and I could fix the power button. You need to press a bit hard while using it, but it worked for me.

20 September 2014

Sjors H. of Waddinxveen in the Netherlands sent me a story and picture about replacing capacitors in his Nespresso XN2105:

Your blog on the Nespresso is repairs is impressive. I made my wrench from an Ikea adjustable foot for a drawer. I’m from the Netherlands and my Nespresso XN2105 blinked irreguarly, while heating up and gave only a little water afterwards. After disconnecting the flow sensor, I got a full cup of water. It turned out to be the 680nF capacitor that had only 100nF of its capacity left. I replaced it with 470nF I had laying around and the machine works for now. I also put some conductive glue on the pads of the buttons to get them working well again. I hope your blog will help many people to repair their machine.

6 October 2014

Pedro A. of Lisbon, Portugal sent his thanks for helping him repair his Nespresso XN2001:

I could not let my day finish without thanking you for the Nespresso oval screws hack :)

As I stumbled on your pages, the idea of getting on the queue to have a chance of trying one of your sockets crossed my mind a few times, but as long as I read more and more ways to hack the damned oval screws I gave a try to the melted BIC pen. Well, it worked like a breeze :)

Five minutes (or less) to get to know where the silicone button had gone (literally gone…) after half an hour trying to access the screws with pliers.

Please accept my enthusiastic salute to ALL of the people who contributed to make life a little less hard to the rest of us. The idea of a world wide traveling socket just made my day and I wonder where this civilization could reach if we acted like this in so manny different activities.

My silicone button is ruined (FUBAR, actually) and I am wondering in ordering a replacement or try one the third party button solutions I saw on your blog. In the case that you want another repair story, I enclose a couple of pictures.

Thanks again for maintaining this kind of public service ;)

13 October 2014

Eros C. from Italy reworked a coffee capsule to fix a leak, here’s his story with many illustrations:

Hi Chris, thank you a lot for your blog… i used some info that i’ve found on your blog in order to repair my nespresso coffee brewing machine i have at work..

The original problem was that using the compatible capsule the capsule holder inside the central brewing unit (CBU) of the nespresso machine went loose.. so when we are going to use again the original nespresso capsule instead of the compatible (hard plastic type) the water injected inside the capsule was leaking from the capsule holder (when you was making the coffee) from the bottom inside the waste capsule container.. the water was not going only through the capsule to the ejector that let the coffee flush on the coffee cup but the same water was leaking from the holder through the bottom ending in the waste capsule container.

i used the bic building socket guide in order do take apart the nespresso en 95 coffee machine.. some photos i saw to organize my idea and make a plan of action..

then i fixed the nespresso en 95 leakege (fig.0) simply using a used nespresso capsule.. here’s my procedure.. sorry i didn’t have any camera or phone with me so i didn’t take photos of the whole process … i hope the information i’m going to send to you will be helpful for some other guys…

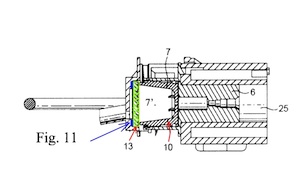

first of all take apart the nespresso (or krups) coffee machine until you can see inside the CBU (compact brewing unit) fig.1 , the CBU from the upper will looks like in the fig.2 and moving the lever you will open the capsule holder (part signed with A) after that then you will see the inner plate fig.3 , now simply prying gently with a screwdriver in the points indicated in the fig.3 you will see the front plate popping out from the CBU because there’s only a smaller lever that hold it.

Now take a used nespresso capsule and empty it fig.4 , wash it and cut all the way around over the point indicated by the red arrows in fig.5 , now you will obtain a sort of alluminium disk with a thicker rolled edge like fig.6, now cut the outside rolled edge in the points shown by red arrows in fig.7 because it will be too much thicker for our purpose, at the end you will have an alluminium spacer like fig.8 , a sort of alluminium ring or washer.

Now look carefully at the fig.9 , you will see the capsule holder signed with n.10, it is the part that moves back and fort when you will activate the coffee machine lever, then you will see the inner plate (the one you pryed out before with the screwdriver) signed with n.13 , and the place where you will have to put the alluminium spacer/washer obtained cutting the nespresso capsule because it is indicated by the blue arrow ..

After that you will have to put the inner plate back in it’s position and thanks to the lever that moves back and forth the nespresso capsule holder you will have to press the inner plate back in place.

OK, now you will have almost the job done..

Put together the nespresso coffee machine and if you have done the process in the right way you will have the water leakage problem solved easy and peasy… < all the best from eros in italy … a nespresso coffee machine fixed with a nespresso capsule.. :-)

14 October 2014

Michael N. of Thessaloniki, Greece writes that he machined tools to turn the oval-head screws and is offering them for sale:

I want to thank you for your special blog about repairing a nespresso machine. I live in Thessaloniki, Greece and I own a tool and die machine shop.

I found your blog in search for solutions in my problem. My Krups Xn2005 was not working properly. After a second the cup button wouldn’t pure coffee and the machine was shutting down. It was the same problem with a fellow from South Africa I think but there was no solution posted.

So I made an oval head key to open and make a little inspection wishing it was just a dirty button. Unfortunately that was not my problem and after changing a capacitor that was dead didn’t manage to fix. So I called the nespresso club and they told me that it is repairable and it will cost €40. So I did. And now it is working again.